Kiesling Refrigerated Vehicles - about us

We are the leading manufacturer of refrigerated vehicles based in Dornstadt-Tomerdingen near Ulm. As a family-run company, we have been developing individual solutions for the transport industry for more than 50 years and produce our products with over 130 employees in Germany.

No. 1 in Quality, Innovation & Service

-

Quality

The durability and quality of our products is our main focus! Kiesling refrigerated bodies are designed for the longest possible use and achieve the highest resale values on the market.

-

Innovation

We continually improve our products through constant innovations. This increases the service life of the vehicles and reduces emissions for the benefit of our customers and the environment.

-

Service

We keep our customers' cold chain running through outstanding service. This way, food waste can be reduced and resources conserved.

"While others are talking, we deliver"

- Herwig Kiesling senior, 1973 -

The motto of our company founder still applies today: We are the first port of call for refrigerated vehicles. We stand for premium quality, groundbreaking innovations and excellent service.

Our brand promise

About Us

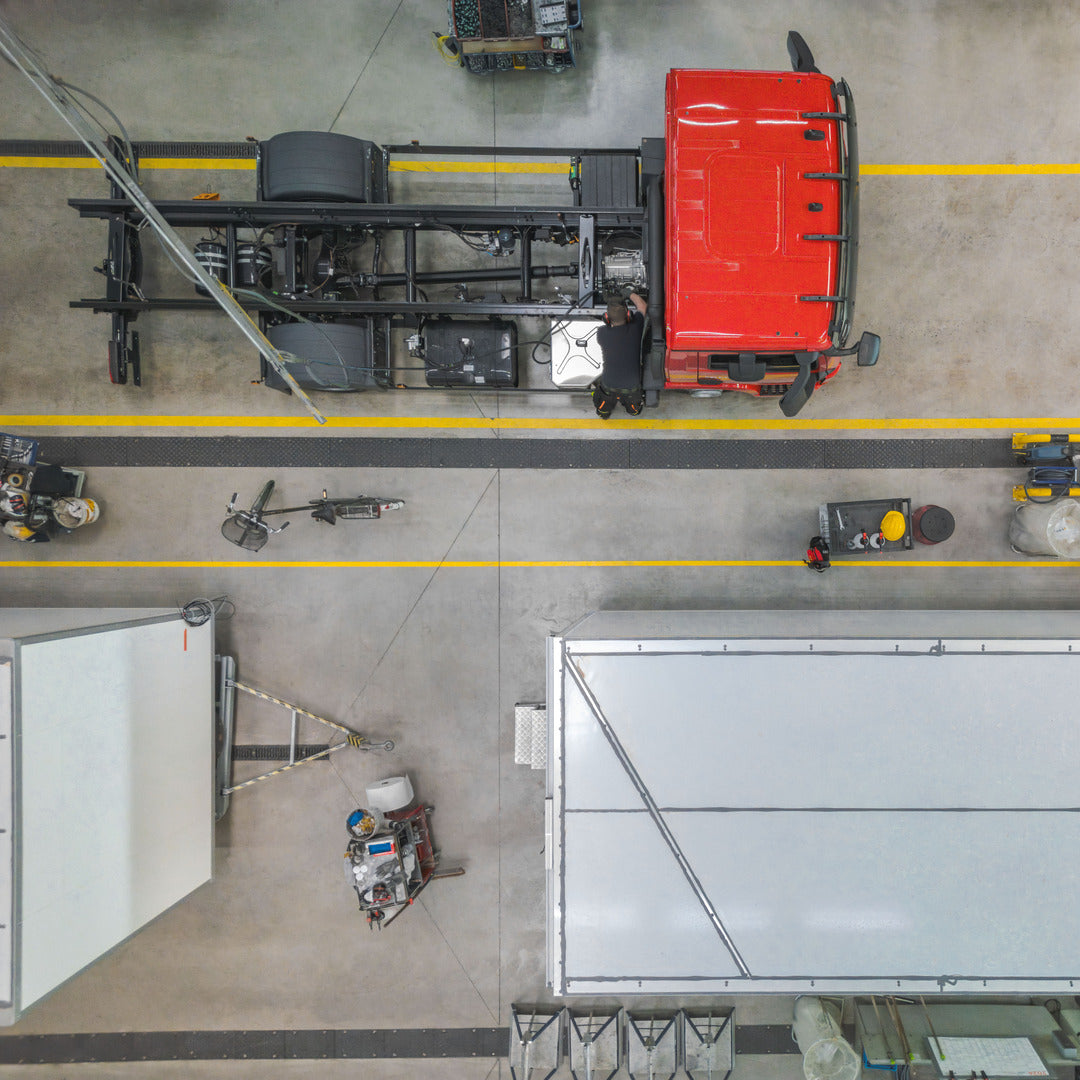

Made in Germany

Kiesling refrigerated vehicles are developed and manufactured in Germany. The factory is placed in Dornstadt-Tomerdingen near Ulm. The FIP bodies (Fully Integrated Panel) are produced here using the latest equipment and are the company's trademark. The unique production process gives the bodies long-lasting insulation and maximum stability, and the refrigerated bodies are also recyclable at the end of their use.

About Us

Over 50 years of expertise

In addition to modern production, it is the Kiesling employees who stand for the highest quality with their know-how. This knowledge is constantly being developed further through training and further education and the company's procedures and processes are continuously being improved. With vehicles that are quickly available, we also offer our customers the fastest route to a new refrigerated vehicle.

About Us

Competent & customer-oriented

Personal contact and customer orientation are our top priority. Our competent team focuses on individual support. Customers are offered suitable solutions for all temperature ranges and individual requirements. As a family business, we stand for responsible and sustainable action.

History

-

1973: Founding

The company was founded by Herwig Kiesling senior in Ulm-Lehr as Herwig Kiesling, Livestock and Meat Vehicles.

-

-

1980: New building

New construction of a production hall in Dornstadt-Tomerdingen.

-

-

1990: Management by Peter Kiesling

Peter Kiesling joins the company and takes over management at the age of 27.

-

-

1995: Quality Management

First-time certification of the quality management system according to DIN EN ISO 9001.

-

2001: Production expansion

Production expansion to a total of 5,000 m² for the production of over 500 refrigerated vehicles.

-

2004: 1st Trailer Innovation Award at IAA

Winning the most important industry award. The flexible partition wall Eco Cool Swing is awarded. Today, its successor Cool Slide is the market standard.

-

-

2005: Foaming plant

Investment in our own foaming plant. Over 800 refrigerated vehicles are already being produced this year.

-

2006: HACCP

Kiesling refrigerated bodies are the first bodies ever to comply with the HACCP guidelines of TÜV Süd.

-

2006: Mercedes-Benz Van Solution

As a system partner of Mercedes-Benz, Kiesling supplies the Cooler Flitzer on Sprinter as a factory solution.

-

-

2010: 2nd Trailer Innovation Award at IAA

The first recyclable refrigerated body with a TÜV-certified recycling rate is awarded a prize. The first photovoltaic system goes into operation in the factory and supplies green electricity.

-

-

2011: Production expansion

Investment in new warehouse and production halls including expansion of the production area to almost 8,000 m². Production of over 1,200 units.

-

2012: Office expansion

Expansion of office space including reception area and training room.

-

2014: Energy & Environmental Management

Certification of energy and environmental management according to DIN ISO 14001 or DIN 50001.

-

2016: 3rd Trailer Innovation Award

Trailer Innovation Award for the Home Delivery Flitzer, the ideal vehicle for home services.

-

2018: Participation in AddVolt

The investment in AddVolt is groundbreaking for the electrification of refrigerated vehicles. AddVolt is now the market leader in the field of battery packs for trailer refrigeration applications.

-

-

2020: Climate-neutral production

By expanding the Photovoltaic system to a total of 510 kWp, more energy is generated than consumed over the course of the year. The company is therefore climate-neutral according to Scope 1 and 2.

-

-

2023: 50th company anniversary & management by Niklas Kiesling

For the anniversary year, Niklas Kiesling, the third generation, takes over the management.

-

-

2024: First refrigerated body on eActros 600

For the world premiere of the eActros 600 from Daimler Truck AG, Kiesling is supplying the appropriate refrigerated body for the presentation at the IAA 2024.

-

-

2025: 2nd place International Trailer Award

The Kiesling power storage station is honored at the International Trailer Award.

-